Carbon is a material that has no equal.

All our bike forks are made of this material.

Many of our bikes are also delivered to their lucky owners equipped with a pair of carbon wheels.

A carbon frame inherently offers the best low weight to maximum stiffness ratio than a frame made from any other material.

Our frames are made tube by tube. I will detail the manufacturing process below.

You'll see, it's pure craftsmanship using extremely technological materials.

Did you know, for example, that our Italian supplier is the same one that supplies Ferrari and Ducati?

Solid as references, right?

Come on, have a coffee, I'll give you the details:

The choice of tubes

Thickness of tubes, nature of fibers, diameter, general shape, etc.

There is an absolutely mind-boggling choice of tubes available for Carbonara.

All the tubes we have selected are made in Italy.

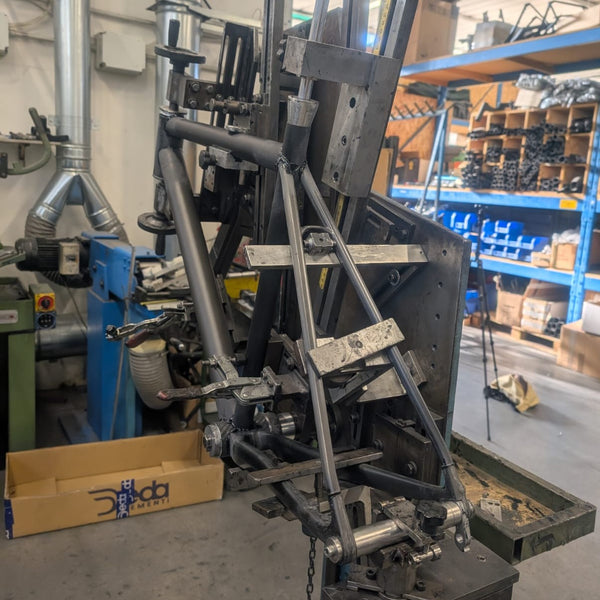

Hop on the jig!

Very similar to what you find for the manufacture of a steel, aluminum or titanium frame, the tubes are positioned on a jig.

The angles are determined.

The alignment is checked.

Everything is held in place using strong polymer glue.

Look at that!

It's starting to look like a bicycle frame!

On the other hand, don't ride it in this state if you want to keep your teeth in your mouth.

The next step is super important!

Heaven for the weightweenies™!

Well, I lied a little when I said that this step was super important.

This is just for fun.

As is, 652 grams for the frame. Not bad, huh?

Snip it!

Here we are in the magic stage. The famous one!

The one that will provide most of the rigidity and resilience of the frame.

Several pieces of Kevlar fibers (the yellow ones) and carbon are cut.

Expert hands

It's time to apply the cut pieces to the joints.

The fibers are braided.

Their orientation is crucial; it will determine the stiffness and compliance of your frame.

Their nature will also play a role.

4k carbon provides a lot of rigidity.

Kevlar gives it a certain resilience.

Time for some vacuum and let's get things heated a bit

Then there are a few trips to the autoclave oven.

By creating an air vacuum, you allow the different layers of carbon to adhere optimally, thus avoiding the terrible "voids" which jeopardize the solidity of your frame.

Shine bright like a diamond

At the end of the process, the frame is impeccable. Ready to be painted.